High Efficiency City Water Whole House Clack Softener And Purification (Chlorine Removal) Dual-Media System With CSI Bluetooth Control Valve And Brine Tank

$3,394.50 Original price was: $3,394.50.$3,094.50Current price is: $3,094.50.

4 interest-free payments of $773.63 with Klarna Learn More

4 interest-free payments of $773.63 with Klarna Learn More

-How A Water Softener Works-

Water hardness is derived from Calcium and Magnesium minerals that have been dissolved into the water under the earth’s surface. These minerals are found in limestone deposits and are the source of hard water. The amount of hardness in a given water supply is dependent upon the quantity of Calcium and Magnesium present and the length of time water has been in contact with them. This can vary dramatically from well-to-well and, for this reason, a water analysis is imperative in order to determine the proper treatment method. The degree of hardness increases as the concentration of Calcium and Magnesium “ions” increase and is measured in Grains Per Gallon (gpg).

The problem of hard water in the home / business comes to light in many facets of daily use. Water spots and scum left behind on bathtubs, fixtures and showers; wear and tear on appliances; calcium build-up in hot water heaters and piping; and greater amounts of soap and detergents being used are just a few examples.

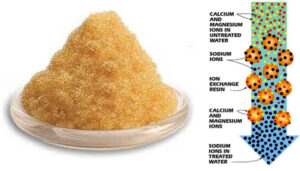

The modern water softener is designed to reduce hardness ions and their unpleasant side effects. Special resin beads in the softener mineral tank are used to change hard water into soft water. The surfaces of these beads are covered with sodium ions. As hard water enters the mineral tank and comes into contact with the resin, an exchange of ions takes place as dissolved Calcium and Magnesium ions cling to the resin surface and sodium ions take their place, thus softening the water. This process is called Ion Exchange. Over time, the sodium ions used for the exchange process become depleted and must be replenished.

The water softener provides a Regeneration process whereby brine solution enters the mineral tank, driving-off the collected hardness ions and replenishes the surface of the resin beads with more sodium ions. This process is automatically initiated by the control valve on the mineral tank. The regeneration process has five basic cycles as follows:

1. Backwash – The control valve directs the water flow in a reverse direction through the mineral tank, separating the

resin beads and flushing any accumulated particles to a waste drain.

2. Brine & Rinse – In the first part of this cycle, the control valve directs brine solution downward through the mineral tank, driving-off collected hardness ions and replenishing the resin beads with sodium ions. The second part of the cycle rinses hardness ions and excess brine from the mineral tank to the waste drain.

3. Rapid Rinse – The control valve directs the water flow downward, settling and re-compacting the resin bed.

4. Brine Refill – The control valve directs fresh water into the salt compartment to create new brine solution for the next scheduled regeneration.

5. Service – This is the normal “operating” cycle where hard water enters the mineral tank, comes into contact with the resin beads and exchanges hardness ions for sodium ions – the water then becomes “soft” and ready for use.

-Pre-Installation Check List-

A water test should always be performed in order to determine total water hardness (in gpg) and total dissolved iron (in parts per million – ppm). This is critical for proper equipment selection, sizing and for determining the program for regeneration frequency. If heavy concentrations of iron (above 5 ppm), iron coloration, iron bacteria or sediment are present, filtration prior to the softener will most generally be required. Certain states may require a licensed plumber for installation.

Note: Flexible water supply connectors and flexible drain line tubing may not be allowed in you locale. Please check with local plumbing code officials prior to installation.

Installation Requirements

• A level floor position ahead of piping into water heater.

• Unit must be installed at least 10’ ahead of the inlet to a water heater to prevent damage due to back-up of hot water.

-Major System Components-

1. Brine Tank – This tank holds the salt that is added to the softener. This salt is dissolved with water to form a brine solution used in the softener regeneration process.

2. Resin Tank – This tank contains the ion exchange resin media. Water flows through the resin tank under pressure to come into contact with the resin for water softening.

3. Control Valve – The valve directs water through the resin tank for water softening and controls the flow of

water / brine for the regeneration process.

-Softener Location / Other Requirements-

• Locate the unit near an un-switched, 120 volt / 60 Hz grounded electrical outlet.

• Check for distance and proper drain installation (e.g. floor drain, washing machine standpipe).

• Determine type and size of piping required for softener connection (e.g. copper, galvanized, PVC plastic).

Note If household plumbing is galvanized and you intend to make the installation with copper (or vise versa), obtain di-electric unions to prevent dissimilar metal corrosion.

• Where the drain line is elevated above the control valve or exceeds 20 feet in length to reach the drain, use 3/4″ I.D. drain line tubing instead of 1/2″ I.D. Drain line tubing is not included.

• All plumbing lines not requiring “soft” water should be connected “upstream” of the softener.

• The brine tank drain line is gravity flow and must discharge below the overflow fitting.

• The brine overflow is provided as a back-up in the event the safety float shut-off should fail, allowing the brine tank to overfill. This drain connection would then carry the excess water to the drain and prevent flooding of the floor. Therefore, no liability will or can be assumed by the manufacturer of the softener should this occur.

Caution : If sweat soldering copper pipe (remember to always use lead free solder and flux), cover bypass valve with wet rags to prevent heat damage to connections and control valve! If using PVC or plastic pipe primers and solvent cements specifically recommended for use with potable water are required.

• Do not “TEE” to the main drain line from control valve.

-Filling The Brine Tank With Salt –

To expect a high level of performance and reliability, a salt manufactured specifically for water softeners must be used. Salt of this grade is virtually free from dirt and other particulates that would eventually cause the softener to malfunction. A pellet type salt is recommended, although any high quality water softener salt (such as solar salt) will suffice. If iron is present in raw water, use of iron inhibiting salt is recommended. The salt level will decrease after each regeneration cycle. Consequently, the salt compartment will need to be checked and replenished periodically.

1. Fill the brine tank or salt compartment with water softener salt as described above. This will be approximately 250 pounds of salt. (150 lbs. for cabinet models.)

Warning : Do not fill salt above level of the brine well.